The last few years we have seen quite a few issues repeated on PCB design that can easily be avoided. So here are 8 things to consider before you begin a new PCB Design.

1. Before you even start s new PCB Design, consider the following.

Depending the product’s size requirements, there are several factors to consider. Board size, cost to manufacture and time it would take to layout. Generally a large board may be easier to route, but cost more to fabricate. A smaller board would cost less for the fab in terms of square inches, but may cost more due to multiple layers, and may take longer to layout.

2. Factor in the cost of component size.

For passives, roughly 0603 size parts will probably be the sweet spot in terms of lowest cost. Precision Technologies can assemble down to 0201 parts, but not all manufacturers will. 0603s are also easy to rework, and are manageable if you feel the need to hand solder a few.

3. Manufacturing thermal concerns when laying out your board.

Very large parts next to very small parts can cause problems. The large parts will act a bit like a heat sink and may prevent the solder for the small part from melting properly. The same thing can happen with internal copper planes that overlap on half of a small part, but not the other.

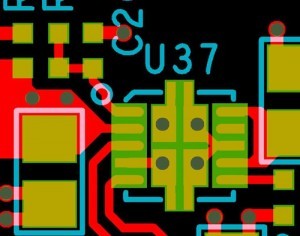

4. Give extra care to the clarity of reference designators and polarity markings.

Make sure that it’s very clear which designator goes with which part, and that there isn’t any ambiguity in polarity markings. Take special care with LEDs, as manufacturers sometimes swap polarity markings between the anode and cathode – yes, the exact same mark can mean anode on one LED and cathode on another. Also, do your best to keep reference designators off of vias or any other spots that might break up the text.

5.Check component distributors for parts availability.

Most commonly we see BOMs with parts that have a either a long lead time or part that are obsolete. Consider substitutes or choose more widely available components.

6. Check out any exotic or new parts.

Some parts, these days, are only available in super small wafer scale BGA, or small QFN form factors. Take a look at your integrated circuits and make sure they come in packages that you’re comfortable working with.

7. Give your files a double check before sending for quote.

Make sure you have the correct versions. Bills of materials are especially susceptible to having bits of information out of date that might cause delays. Mark parts that do not need to be placed “DNP”

8. If you’re sending in a parts kit, double check that you have all of the parts plus a few extras.

Ensure you have part number and reference designator on the individual part bags. Manufacturing is just putting parts on boards, but it’s doing so with a whole lot of variables. A few extra checklist steps can go a long way toward removing variability of those variables.

For more information about our PCB Fabrication and PCB Assembly services, contact us Precision Technologies today by calling 847-439-5447 or email.